Fast Turnaround for Airports Repairing Concrete with Rapid Set Concrete

On a daily basis, airports exceed the capacity for which they were designed. Our nation’s runways and taxiways are taxed to the limit and are in need of repair and upgrading on a continual basis.

Regular Portland Cement (RPC) can take days, even weeks, to achieve the required compressive strength. Closing a runway for even one day, much less several days, can throw an airport into turmoil with delayed flights, irate customers and can result in lost revenue.

The solution for timely airport concrete rehabilitation projects is to use the George L. Throop Company in combination with Rapid Set® Cement (RSC). By using Rapid Set , the airport runway, taxiway, sidewalk, lighting upgrade, or hardstand can be reopened in two hours or less after concrete placement — saving you time and money. In addition, Rapid Set cement is more durable than Portland cement and exceeds standards set by FAA-P501 specifications.

Repairing airport runways, taxiways, lighting, and hardstands has to be done quickly with knowledge and expertise. Mistakes with concrete can be costly. The Throop Company has had experience with all types of weather and temperatures which can play an important part in making sure that the concrete sets properly.

In addition to different environmental conditions, we have the experience working with tight time schedules, going through security and adhering to and keeping up with safety regulations. We have many years of experience working on airports all over the United States.

After Rapid Set has been produced and placed by the George L. Throop Company, various contractors performe the completion of the placing, finishing, and curing. The taxiways, runways, sidewalks, hardstands, runway crossing, lighting upgrades and even earthquake repairs allowed the airports to return to service within a few hours of placement.

We have Performed the Following Concrete Repairs at International and Regional Airports

- Airport concrete runway and tarmac replacement

- Airport concrete taxiway repair

- Airport concrete hardstand repair or upgrade

- Airport runway crossing concrete replacement

- Airport runway lighting upgrades

- Airport sidewalk repair

- Airport earthquake repair

View more detailed information below on airport concrete repairs by Throop Company

Airport Taxiway Repair

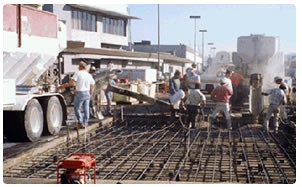

Airport taxiways are the link between the airport runway and different areas of the airport. Most airport taxiways get heavy use, especially in busy airports. After years of supporting the weight of massive airplanes, the concrete in taxiways needs to be replaced to reduce runway incursions and improve surface navigation. At the airports listed below, different contractors were used to remove the existing concrete and to prepare the area for Rapid Set® concrete placement.

After the Rapid Set was placed by the George L. Throop Company, various contractors performed the placing, finishing, and curing. The taxiways were returned to service within a few hours of placement. We completed each of our airport taxiway repair projects on time.

Airport Hardstand Concrete Repair

Bigger commercial jets are required to park closer to airport terminals which requires the existing hardstands to be remodeled in order to handle the extra weight. Existing asphalt usually cannot handle the weight of heavier aircraft. That is where the George L. Throop Company comes in. The thinner hardstands are replaced with Rapid Set concrete and within a few hours of placement, not days, the area is returned to service.

Runway Crossing Replacement

Installation of new fiber optics and power is quite often required at airports. Usually that means the airport runways and concrete airport crossings need to be torn up to have the new technology installed. It can be a big job with digging trenches 48 inches x 48 inches x 200 ft. for the new fiber optics and power lines. Excavation usually takes place with two backhoes face-to-face from the center of the runway; four-inch conduit (16 pieces) are placed in the trench.

Rapid Set® concrete is the smartest product to use to back fill the trench so that the runway can be up and running within 1-1/2 hours after the concrete is placed. The penalty for not opening the runway on time can be as high as $1,000.00 per MINUTE or more. On this airport runway construction project we had to be finished by 5:00 a.m. Because of the time-saving properties of Rapid Set cement, in combination with our expertise in using it, we finished with no delays and the airport crossings we worked on were opened up on time.

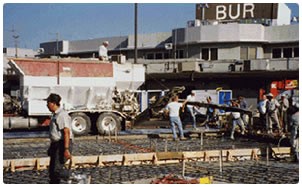

This work was performed at the Bob Hope Airport in Burbank, California, where the Throop Company worked as a sub-contractor under a general contractor.

Airport Runway Lighting Upgrade Concrete Repair

Over time the FAA requires airports to upgrade their lighting systems for aircraft runways in order to meet national standards. At multiple airports, listed below, the George L. Throop Company has produced Rapid Set® fast setting concrete to backfill trenches after new lights were put in place. Using Rapid Set cement allows aircraft to use the runway or taxiway two hours after the quick-setting concrete has been placed. Quite often black oxide color is mixed in to match if there is existing asphalt. Because of our expertise and that Rapid Set concrete comes to strength so quickly, the projects were done quickly and allowed the airports to open back up to air traffic within record time.

Airport Sidewalk Repairs

Sidewalks at airport passenger drop-off points are extremely busy places getting continual abusive use. Using Rapid Set® concrete to repair airport sidewalks and walkways eliminates the need to use plates or barricades that could be trip hazards. All work is typically completed at night with normal airport usage open to the public by 5:00 a.m. With each project and location listed below, we were on-time.

Besides the quick return to use that occurs when using Rapid Set concrete, the other advantage is that there is no damage to the walkway or sidewalk from luggage wheels, carts, or high heels because of Rapid Set attaining high strength so early. In addition, color of existing concrete can be matched.

Airport Earthquake Concrete Repair

The George L. Throop Company was contacted by the Bob Hope Burbank Airport engineer to help save a multi-level parking garage damaged by the 1994 Northridge earthquake. After analyzing the problem, the solution decided upon was to wrap the numerous damaged columns with custom fabricated steel columns welded in place. Rapid Set concrete was then used to fill the void between the column and the steel jacket that had just been welded. The parking garage was returned to service in record time in just a few days after the earthquake

Concrete Production Work was Performed at the Following Airports

- ATL – Hartsfield-Jackson Atlanta International Airport , Atlanta, Georgia

- LGA – LaGuardia Airport, Queens, New York

- BUR – Bob Hope Airport, Burbank, California

- LAX – Los Angeles International Airport, Los Angeles, California

- SFO – San Francisco International Airport, San Francisco, California

- ONT – Ontario International Airport, Ontario, California

- SAN – San Diego International Airport, Lindbergh Field , San Diego, California

- SNA – John Wayne Airport-Orange County, Santa Ana, California

- SEA – Seattle-Tacoma International Airport, Seattle, Washington