- Home

- Specialty Concrete

- High Density Concrete Production

High Density Concrete Production

High Density Radiation Shielding Concrete

High density concrete is fundamental for radiation shielding, counterweights, and other applications where the high density is essential. It exhibits better shielding properties, acting as a protective layer against harmful radiations, which can absorb and attenuate harmful radiations including neutrons, X-rays, and gamma rays. High density concrete is about a 50% higher density than conventional concrete.

Concrete is an almost perfect material for the medical field with shielding properties against neutron and gamma-rays in hospitals and clinics due to its intrinsic water content and relatively high-density which makes it the most widely used material for radiation shielding.

Throop Company High Density Concrete Projects

The Throop Company has produced concrete mixes up to 6,750 lbs per cubic yard or 250 lbs per cubic foot.

- Radiological Vault at City of Hope, Irvine, California

- Radiological Vault at City of Home, Duarte, California

- China Lake Ridgecrest, California

- Throop produced over 1,000,000 lbs of high density concrete in a day (a cubic yard weighs 6,750 lbs)

- Exxon – High voltage conduits

- The Throop Company produced heat-releasing concrete that surrounded high voltage conduits that generated a lot of heat. The mix design of the concrete that was used allowed the heat to be released.

Key Production Steps for High Density Concrete

The Throop Company is well aware that high density concrete production involves several key steps and considerations to ensure the desired density and performance. They know that it’s very important that the aggregates are properly selected based on their physical properties such as bulk density, specific gravity, and availability.

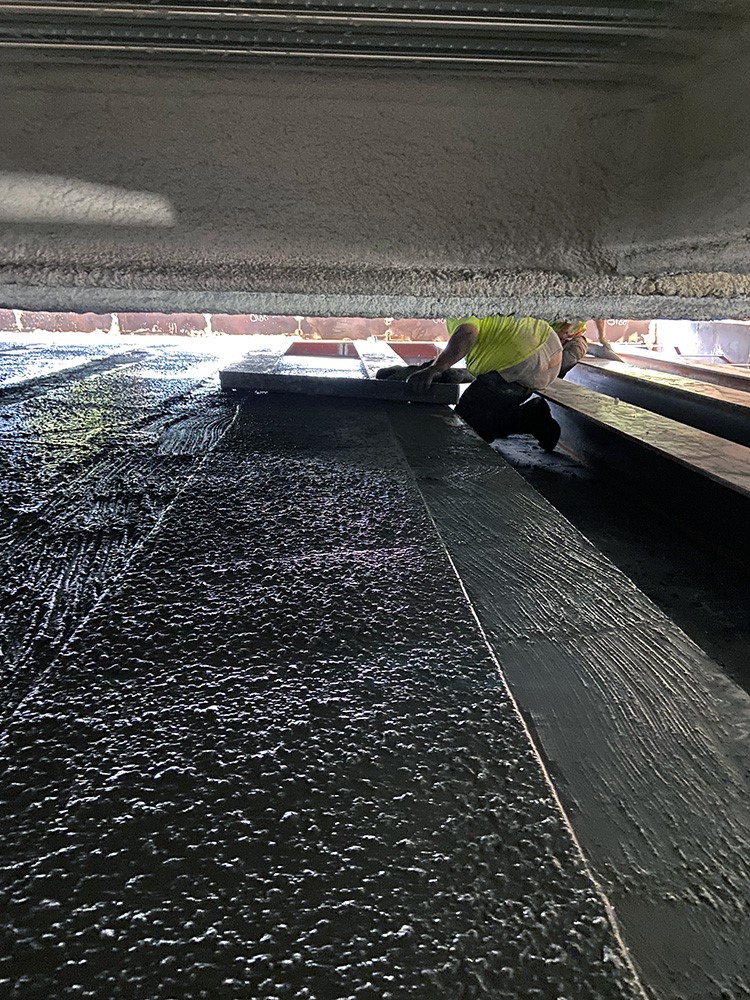

The conventional method of mixing and placing high-density concrete can be used, but special attention must be given to prevent overloading the mixer and avoid excess mixing to maintain workability and prevent bleeding. High-density concrete requires strict quality control to ensure it meets the required density and performance standards. This includes controlling the water/cement ratio, using appropriate admixtures, and employing good compaction techniques, which is accomplished using volumetric concrete mixers.

While high-density concrete usually costs more than normal concrete, it offers excellent shielding from harmful radiation and is durable and low-cost compared to alternatives like composite lead or steel shields. Concrete produced with heavy aggregates like iron ore and magnetite helps increase the concrete density and fight against radiation.

The production of high-density concrete is a specialized process that requires careful planning and adherence to strict standards to achieve the desired properties and applications.

Composition and Variety of Applications for High Density Concrete

High density concrete can be used in a wide variety of applications by

adjusting the admixtures.There are unique properties to high density

concrete such as its composition, and mix proportions.

This type of concrete usually includes aggregates such as iron ore, magnetite, ilmenite, barite, ferrophosphorus (primarily composed of iron and phosphorus), limonite, hematite, goethite, or even steel punchings and steel shots. It all depends on the specifications in the project. The level of density will depend on the types of aggregates used in the composition.

The usual materials like water, cement, and admixtures that are used in normal density concrete are also used in high density concrete. However, because the aggregates can vary, special care and attention is required during batching, mixing, handling, transporting, and placing of high density concrete.

The intended use, availability, physical and chemical properties and cost all needs to be taken into consideration before getting into the production of the high density concrete and the Throop Company can help with guiding the team through the project.

Uses of High-Density Concrete

Due to its unique properties and functionalities, high density concrete can be used in a wide variety of applications, not just the medical field. Some common uses are radiation shielding, counterweights to help distribute weight evenly to certain structures, and underwater structures since it can withstand the immense pressure created inside a water column.

Advantages of High Density Concrete

- High density concrete can enhance the weight-bearing capacity of structures. Higher-density concrete can support heavier loads without lifting the structural stress and dimensions. This can be a perfect choice for structures where they have limited space but need to withstand significant stresses.

- It has excellent thermal conductivity when compared to normal concrete. It can dissipate heat and reduce the risk of thermal cracking when the concrete is exposed to rapid temperature fluctuations.

- High density concrete has space savings. It has an increased strength-to-weight ratio. It helps create more compact structural elements, resulting in significant space savings. This is best suited for urban areas where the land space is very limited.

- There is also a cost cutting aspect, in the long run, of using high density concrete. The initial investment of high-density concrete may be higher than that of conventional concrete due to the requirement for heavy aggregates but it benefits you in several ways, like reduced thermal cracking and potential space savings.

High-density concrete can be used in many construction projects as it offers numerous advantages to the structures over normal concrete. Choosing quality aggregates is very important to achieving the desired properties.

Have a question?